Prior to mounting, non-tailor made heating cables must be tailor made. For this the termination kit is used. For better heat transmission at plastic pipes or cast-iron pipes, alu-foil, alu-tape or similar are used before the tracing.

Mounting of heating cable on pipes

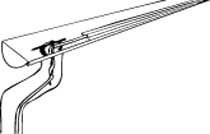

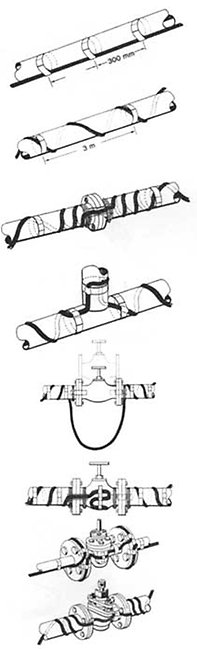

Laying along the pipe.

If the heating cable is laid along the pipe, it must follow the underside of the pipe and be fixed at each 300mm.

Spiral laying.

If the heating cable is spirally wound around the pipe, this has to be made with regular distance over the entire pipe length to obtain even heat distribution.

Mounting of heating cable on flanges

Before and after flanges, the heating cable must be wound spirally closer.

Please note! rough edges must be deburred or covered by an aluminium plate.

Mounting of heating cable on T-junctions

Normally, each arm on a big T-junction is wound by a separate heating cable.

At shorter T-junctions a single cable is normally laid along one of the sides of the T and returns along the other side to the main pipe line.

Mounting with valves

Extra length heating cables for valves.

To enable the service of the valve the heating cable must be wound across the valve.

Place the heating cable so that the valve can be removed without damaging. This is made by placing the heating cable on the pipe on both sides of the valve, and then letting adequate extra cable hang for the valve. The extra length is fixed in a Z at the bottom of the valve.

Mounting on big valve flanges.

If the valve has a relatively big flange, extra heating cable must be wound once around the edge of the flange.

Mounting on small valves.

If the above mounting is not possible, extra heating cable is placed on each side of the pipe next to the valve or the flange.

%20Kabelvifte.jpg)